Photo By Lance Cpl. Joshua Brittenham | PHILIPPINE SEA (Aug. 24, 2020) Staff Sgt. Jack Hubbard, a radio technician with Combat......read moreread more

Called the Green to Blue Program it consists of a Marine going TAD to PMO for six months to receive on-the-job training as a police officer while still in the Corps. According to Betty James-Ashby, human resources specialist with PMO, six months of experience is required for transition to the civilian police force and program Green to Blue is. Animated Marine Corps Freeware MCM ARS Volunteer Management v.1.0 This volunteer management project is an extension of the Sahana disaster management system, specifically targeted for use by Amateur Radio Operators in support of the Marine Corps Marathon. MARINE CORPS MANUAL CHANGE 2 THE COMMANDANT OF THE MARINE COR WASHINGTON 11 Jan 1984 1. Remove and destroy present pages 1-11, 1-12, 1-23, 1-24, 2-17.

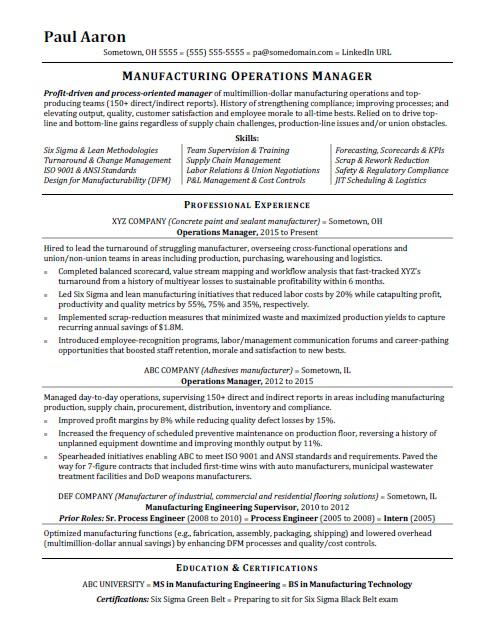

Photo By Lance Cpl. Joshua Brittenham | PHILIPPINE SEA (Aug. 24, 2020) Staff Sgt. Jack Hubbard, a radio technician with Combat Logistics Battalion 31, 31st Marine Expeditionary Unit (MEU), observes a 3D printer as it prints an equipment part used aboard USS New Orleans (LPD 18). New Orleans, part of the America Amphibious Ready Group (ARG), 31st MEU team, is operating in the U.S. 7th Fleet area of operation to enhance interoperability with allies and partners and serve as a ready response force to defend peace and stability in the Indo-Pacific region. The America ARG, 31st MEU team remains the premier crisis response force in the region despite the unique challenges caused by the COVID-19 pandemic. (U.S. Marine Corps photo by Lance Cpl. Joshua Brittenham) see less | View Image Page

PHILIPPINE SEA

10.07.2020

Story by Lance Cpl. Joshua Brittenham

PHILIPPINE SEA (Oct. 7, 2020) – Marines with Combat Logistics Battalion (CLB) 31 are using 3D printing technology to save thousands of dollars and weeks of time for the 31st Marine Expeditionary Unit (MEU) and America Amphibious Ready Group (ARG).

From small parts to more complex designs, the Marines of CLB-31 are assisting in daily functions and cutting back on cost for the Marine Corps. Utilizing developing 3D printing technology, the Marines are assisting with mission readiness not only by providing quality parts, but on-site adjustments and cost efficient materials as well.

'The benefits of using a 3D printer are endless,' said Staff Sgt. Jack L. Hubbard III, a communications electronics maintenance chief with CLB-31. 'We were asked by our Navy counterparts to print a knob used to charge forklift batteries. The cost of the entire unit is $45,000, but it only cost us three dollars to print the knob ourselves.' After printing the knobs, the CLB was also able to add 3D printed handles for Sailors' additional protection when transporting the batteries.

Printing parts on ship cuts down not only on costs but also on time spent waiting for ordered parts, keeping the blue-green team in the fight.

After successfully printing the parts requested by Navy counterparts, the team was requested to assist Fox Company, Battalion Landing Team (BLT), 2nd Battalion, 4th Marines with replacing Combat Rubber Raid Craft (CRRC) handles.

'The CLB-31 additive manufacturing detachment has worked closely with Fox Co, BLT 2/4 staff and has successfully manufactured a working prototype of the replacement part needed,' said BLT 2/4 executive officer Maj. Richard S. Jahelka.

Sgt. Alonzo Longstreet, a radio technician with CLB-31, 31st MEU, took a Combat Rubber Raid Craft's (CRRC) handle and scanned it using a 3D scanner. After removing redundancies and piecing together the model using Cura software, Longstreet printed a functional part to replace the older handle.

Jahelka continued, 'Fox Co reports that the prototype part was successfully installed and that it is functional. They are going to use the lessons learned in this successful prototype to manufacture two more units and are confident that the effort will ensure that all 20 CRRCs maintain fully operational status.'

The BLT tested the handles during a boat raid exercise after they were printed. After a successful training exercise, the BLT reported the handles functioned properly and none of the printed handles had failed. Now that the handles have been tested, the design will be uploaded to a database used by the Marine Corps, allowing for Marines across the world to download and print Longstreet's model.

With thousands of dollars saved, and weeks of time reclaimed, the Marines of CLB-31 will continue to experiment with ways that 3D printing can be used to help the 31st MEU maintain readiness at sea and on land.

New Orleans, part of Expeditionary Strike Group 7, along with the 31st MEU, is operating in the U.S. 7th Fleet area of operations to enhance interoperability with allies and partners and serve as a ready response force to defend peace and stability in the Indo-Pacific region.

LEAVE A COMMENT

NEWS INFO

| Date Taken: | 10.07.2020 |

| Date Posted: | 10.08.2020 21:18 |

| Story ID: | 380402 |

| Location: | PHILIPPINE SEA |

download free, software Marine Corps Green To Blue Program

download free, software Marine Corps Green To Blue Program Military

| Web Views: | 103 |

| Downloads: | 2 |

Called the Green to Blue Program it consists of a Marine going TAD to PMO for six months to receive on-the-job training as a police officer while still in the Corps. According to Betty James-Ashby, human resources specialist with PMO, six months of experience is required for transition to the civilian police force and program Green to Blue is. Animated Marine Corps Freeware MCM ARS Volunteer Management v.1.0 This volunteer management project is an extension of the Sahana disaster management system, specifically targeted for use by Amateur Radio Operators in support of the Marine Corps Marathon. MARINE CORPS MANUAL CHANGE 2 THE COMMANDANT OF THE MARINE COR WASHINGTON 11 Jan 1984 1. Remove and destroy present pages 1-11, 1-12, 1-23, 1-24, 2-17.

Photo By Lance Cpl. Joshua Brittenham | PHILIPPINE SEA (Aug. 24, 2020) Staff Sgt. Jack Hubbard, a radio technician with Combat Logistics Battalion 31, 31st Marine Expeditionary Unit (MEU), observes a 3D printer as it prints an equipment part used aboard USS New Orleans (LPD 18). New Orleans, part of the America Amphibious Ready Group (ARG), 31st MEU team, is operating in the U.S. 7th Fleet area of operation to enhance interoperability with allies and partners and serve as a ready response force to defend peace and stability in the Indo-Pacific region. The America ARG, 31st MEU team remains the premier crisis response force in the region despite the unique challenges caused by the COVID-19 pandemic. (U.S. Marine Corps photo by Lance Cpl. Joshua Brittenham) see less | View Image Page

PHILIPPINE SEA

10.07.2020

Story by Lance Cpl. Joshua Brittenham

PHILIPPINE SEA (Oct. 7, 2020) – Marines with Combat Logistics Battalion (CLB) 31 are using 3D printing technology to save thousands of dollars and weeks of time for the 31st Marine Expeditionary Unit (MEU) and America Amphibious Ready Group (ARG).

From small parts to more complex designs, the Marines of CLB-31 are assisting in daily functions and cutting back on cost for the Marine Corps. Utilizing developing 3D printing technology, the Marines are assisting with mission readiness not only by providing quality parts, but on-site adjustments and cost efficient materials as well.

'The benefits of using a 3D printer are endless,' said Staff Sgt. Jack L. Hubbard III, a communications electronics maintenance chief with CLB-31. 'We were asked by our Navy counterparts to print a knob used to charge forklift batteries. The cost of the entire unit is $45,000, but it only cost us three dollars to print the knob ourselves.' After printing the knobs, the CLB was also able to add 3D printed handles for Sailors' additional protection when transporting the batteries.

Printing parts on ship cuts down not only on costs but also on time spent waiting for ordered parts, keeping the blue-green team in the fight.

After successfully printing the parts requested by Navy counterparts, the team was requested to assist Fox Company, Battalion Landing Team (BLT), 2nd Battalion, 4th Marines with replacing Combat Rubber Raid Craft (CRRC) handles.

'The CLB-31 additive manufacturing detachment has worked closely with Fox Co, BLT 2/4 staff and has successfully manufactured a working prototype of the replacement part needed,' said BLT 2/4 executive officer Maj. Richard S. Jahelka.

Sgt. Alonzo Longstreet, a radio technician with CLB-31, 31st MEU, took a Combat Rubber Raid Craft's (CRRC) handle and scanned it using a 3D scanner. After removing redundancies and piecing together the model using Cura software, Longstreet printed a functional part to replace the older handle.

Jahelka continued, 'Fox Co reports that the prototype part was successfully installed and that it is functional. They are going to use the lessons learned in this successful prototype to manufacture two more units and are confident that the effort will ensure that all 20 CRRCs maintain fully operational status.'

The BLT tested the handles during a boat raid exercise after they were printed. After a successful training exercise, the BLT reported the handles functioned properly and none of the printed handles had failed. Now that the handles have been tested, the design will be uploaded to a database used by the Marine Corps, allowing for Marines across the world to download and print Longstreet's model.

With thousands of dollars saved, and weeks of time reclaimed, the Marines of CLB-31 will continue to experiment with ways that 3D printing can be used to help the 31st MEU maintain readiness at sea and on land.

New Orleans, part of Expeditionary Strike Group 7, along with the 31st MEU, is operating in the U.S. 7th Fleet area of operations to enhance interoperability with allies and partners and serve as a ready response force to defend peace and stability in the Indo-Pacific region.

LEAVE A COMMENT

NEWS INFO

| Date Taken: | 10.07.2020 |

| Date Posted: | 10.08.2020 21:18 |

| Story ID: | 380402 |

| Location: | PHILIPPINE SEA |

download free, software Marine Corps Green To Blue Program

download free, software Marine Corps Green To Blue Program Military

| Web Views: | 103 |

| Downloads: | 2 |

PUBLIC DOMAIN

This work, Additive Manufacturing: CLB-31 Supports the Blue-Green Team with 3D Printing Technology, by LCpl Joshua Brittenham, identified by DVIDS, must comply with the restrictions shown on https://www.dvidshub.net/about/copyright.